Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) dentistry enable dentists to create new false teeth like crowns, dentures, bridges, and many more much faster and easier than before. This is especially true because of the emergence of 3D printing technology, wherein any three-dimensional (3D) design that you come up with can be printed out in real time in 3D, as though you have a personal manufacturing factory right inside your clinic.

This dentistry type has certainly made dental laboratories more dependable and quicker with their denture and orthodontic turnaround time. Since more trusted dental centers like Thantakit are already operating CAD/CAM dental labs, it’s a good idea to learn more about this advanced technology and how it could impact your restorative dentistry needs.

What Is CAD/CAM Dentistry?

CAD/CAM dentistry is a new dental invention or innovation, particularly in the realm of prosthodontics. As mentioned earlier, it’s all about using computers in order to aid dental labs in making prosthodontics in a more efficient manner, usually with the aid of a dental digital scanner to get the mold of the mouth versus a literal mold using molding material placed into the mouth. These scanners are many times more accurate than their mold-based counterparts.

Here are the most frequently asked questions you need to know when it comes to CAD/CAM.

- What Are The Many Names of CAD/CAM? CAD/CAM is also known as CAM/CAD, 3D milling, 3D printing, extraoral or extra-oral scanning, intraoral or intra-oral scanning, digital dentistry, and a host of other high-tech buzzwords. These all refer to CAD/CAM or at least some of the many processes included in it, with digital dentistry serving as an umbrella term for dentistry that’s aided with digital devices like computers, 3D rendering software, digital scanners, and 3D printers or milling machines.

- When Did CAD/CAM Start? According to a review published in the Journal of Prosthodontic Research or JPR, his type of dentistry started back in 1985. Since the mid-1980s, the technology has improved by leaps and bounds, revolutionizing restorative dentistry in many avenues and aspects for both patients and dental professionals. Since then, CAD/CAM dentistry has only gotten better thanks to the advancements in 3D software design and the invention of the 3D printer.

- Why Do Dentists Depend on CAD/CAM? The JPR further elucidates that CAD and CAM are terms used to describe software or programs that make it possible for a dental professional to perform even more complex procedures like cosmetic dentures and orthodontics in a more accurate, faster, and easier manner than before, when they depended on molds and weeks of dental prosthetics creation in the dental lab. It also allows same-day manufacturing of crowns, veneers, and so forth.

- What Can CAD/CAM Do? You can use CAD/CAM in order to create accurate and perfectly fitting crowns, veneers, bridges, onlays, inlays, and so forth from a single ceramic block. Thanks to 3D printers, it’s also possible to print out the prosthodontic teeth you want exactly without wasting material to boot, all in the same day or visit so that you won’t have to wait long in order to get your new teeth attached. The final product is best done with a single ceramic block In order to ensure its toughness compared to other methods of fabrication.

- How Should You Take Care of Your New Restorations? You can use the same oral hygiene regimen of brushing twice a day, gargling mouthwash, and flossing that you’ve been using for your natural teeth when taking care of your dental restorations whether they’ve been made by a traditional dental lab or with CAD/CAM technology. There are a few caveats to this of course, like using a special floss when cleaning out a dental bridge and so forth.

Pros and Cons of CAD/CAM Dentistry

According to the Consumer Guide to Dentistry, there are many advantages to using CAD/CAM dentistry to aid restorative dentistry instead of the old standard of letting the dental lab mill or manufacture new dental prosthetics for a few weeks based on the mold of the patient’s mouth. It includes the following:

- Improved Accuracy: A dental scan is more accurate than a mold of your mouth. The laser light used to do the scan and translate it into a 3D model can take note of nuances, minutiae, and topography in your mouth that a simple mold cannot, especially if you took a colored digital intra-oral scan. Also, if your mouth changes in terms of less swollen gums or extra fallen teeth, it’s easier to do a quick digital scan versus putting on a new mouth mold.

- Shorter Waiting Periods: It takes only 40 minutes to 2 and ½ hours to make dental appliances versus 2 weeks to a whole month. It’s like the difference between email and standard mail in terms of quickness. This also means fewer visits to the dentist, as discussed later on in the other items on this list. Shorter is better in today’s world where everyone’s in a rush.

- One-Visit Procedures: There’s no need for a temporary restoration like a template-based temp crown with CAD/CAM tech because now the whole process can be done in one visit, no problem. Alas, you’ll have to pay extra time in the dentist chair because the visit lasts longer than usual. Still worth it compared to stretching out costs on multiple visits.

- Steep Learning Curve: Some professionals might have to deal with a steep learning curve in order to effectively use CAD/CAM technology, thus not all dental clinics will have it. Only 8-10 percent of American dental clinics have in-house CAD/CAM facilities according to Dentistry IQ. Then again, they might hire a dental technician to deal with the details. There’s also the possibility of dental labs using this tech so there will still be outsourcing involved but at least the turnaround remains fast.

- Not Everyone Can Use CAD/CAM Tech: Like with dental implants, your dentist will first inform you if you’re good to go with CAD/CAM or not. Sometimes, the old methods of making a mold with your mouth is more viable because the tech isn’t available, there are issues with the intraoral scanner, it’s too expensive and you’re willing to wait for the cheaper alternative, you’re not covered by your dental insurance for CAD/CAM, or you can’t handle same-day operations unless you also pay for sedation dentistry because of anxiety issues.

What Are The Processes Involved When Undergoing CAD/CAM Dentistry?

Custom 3-dimensional images of the tooth that’s based off of your dental scan or digital scans of your dental impressions will be created when using CAD/CAM techniques. These scans are many times more accurate than the traditional mold technique, thus ensuring a virtual design for your restorative device that’s a perfect tailor fit to your mouth every time. Milling equipment or a 3D printer is then fed the digital information to get to work on the appliances.

To be more specific, here’s a list of steps involved in a procedure using CAD/CAM as provided by the Dental Economics publication.

- Anesthesia: You will first be anesthetized with local anesthesia to prep your damaged tooth for prosthodontic correction, like for example putting a crown atop a holey tooth with cavities too large for dental fillings to fix. This is to avoid getting your raw tooth nerve or the surrounding sensitive gums to go throbbing in pain.

- Tooth Preparation: Your compromised tooth will be drilled, chiseled, and roughened up in order to make it more receptive to its new prosthodontics. This drilling is why anesthesia is necessary when putting in a new restorative device on your compromised tooth or teeth, especially if it’s a dental bridge.

- Intraoral Scanning: Your prepped tooth or set of teeth will then get an intraoral scan in order to have digital data to feed your computer responsible for the bulk of the CAD/CAM process. This is superior to using molds that are sent to dental labs so as to mill your new false teeth for about 1-2 weeks.

- Restoration Design: A CAD technician will then design the restorative device responsible for restoring your teeth to its former glory in accordance to the data given to him and the recommendations of the dentist. It’s all in 3D that will then be fed to a device for manufacturing purposes.

- Milling or Printing: The CAM portion of CAD/CAM involves printing out the new tooth using a 3D printer and tough textile material you’d normally see used in factories and industrial-grade work. It can also involve using a block of ceramic to mill or cut a tooth out of it.

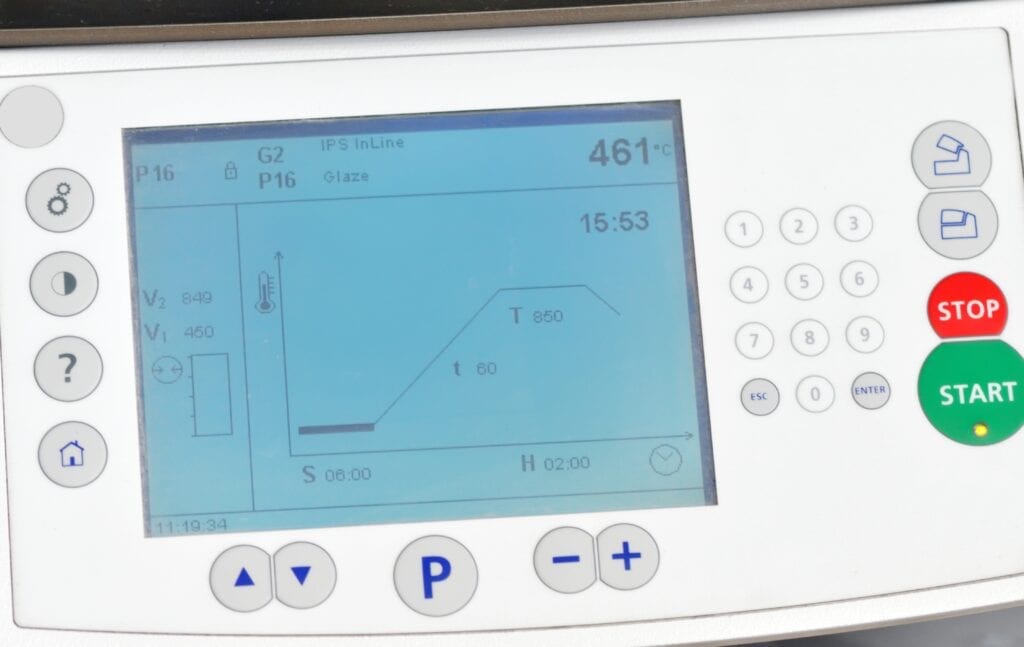

- Sintering and Polishing: When milling a ceramic block into a 3D crown or bridge, it also needs sintering and polishing to make it as tough, shiny, smooth, and brand new as human teeth. 3D-printed restorative devices might also require further sinter and polish but not as much as the ceramic block.

- Cementation: This new prosthodontic device is then placed on your prepped tooth or teeth using what’s known as dental cement. It should be tough enough to last years or decades even when regularly used, but it could give way much sooner when abused (like when you chew gum, ice, hard candy, or cracker nuts regularly). The best cement will make your prosthetic teeth feel so solid and grounded it’s like they’ve always belonged in your mouth.

The Main Appeals of CAD/CAM

According to Dentistry IQ, the computerized milling machine usually carves a solid block of restorative material in order to make the new tooth. The turnaround for this is rather quick, with everything being done in what Dental Economics estimates as 40 minutes to 2 hours and 30 minutes. Although this dental appointment sounds tediously long, the convenience presented is actually impressive. It used to take 2 weeks to a month to get your prosthodontics made at a dental lab.

- Dentists and Patients Love The Quickness: Now you won’t have to wait long. This tech also makes it possible to All-on-4 to All-on-8 dental implantation because the resulting crowns are readily milled or printed for use as needed. You can do many types of services and procedures in one trip at the dentist office versus having to go through a second to fifth appointment back in the day when CAD/CAM wasn’t advanced enough to make this all possible. However, they might prefer to longer manufacturing time because it’s cheaper or they have coverage for that.

- Dental Technicians and Laboratories: Now that the dust has settled and CAD/CAM has only gotten better through the years with cheaper and more accurate 3D printers, advances in scanning technologies, better 3D software, and so forth, does this spell the end for dental labs? Even though dentists can manufacture their own prosthodontics in their clinic without the need for labs, some don’t and only a percentage of dentists do. Other dentists prefer to simply get the help of CAD/CAM laboratories in order to not let go of outsourcing completely.

- The Future Is Now: Whenever new technology arises, the purveyors of the old methods fear extinction. However, they should instead embrace evolution and innovation. Some professionals in the dental industry had more than a little bit of trepidation and ambivalence towards the rise of CAD/CAM ever since it first appeared on the scene in 1985. However, it’s for the best that change happens, because otherwise barbershops would still be doing minor surgeries on top of cutting hair.

Is CAD/CAM Dentistry Right for You?

Technology marches on and that’s a good thing indeed. The dental laboratory could now be found right inside the clinic of the dentist himself, with him or his assistant doubling as millers or prosthodontic makers. You don’t need to outsource your restorative options to a lab any longer. This particular innovation also gets rid of outsourcing costs to boot or at the very least makes them significantly smaller in case you’re outsourcing to a digital CAD/CAM dental lab.

There was originally a fear of CAD/CAM spelling the doom of dental laboratories and dental technicians, with dentists printing or milling out dentures or crowns for use on patients on their own with the ease of printing out documents on a simple computer printer. These fears were laid to rest as CAD/CAM became more ubiquitous, with the demand for high-tech CAD/CAM tech labs and CAD/CAM literate technicians rising. Also, the old method of custom prosthodontic creation still remains as the cheaper alternative.

Lastly, it’s also important to note that even though it’s convenient for a dental clinic to have its own CAD/CAM facility, it’s mostly an optional benefit. Because of this, many clinics still prefer letting dental labs provide CAD/CAM services for them.

Thantakit International Dental Center is Thailand’s longest established dental center. Situated in Bangkok, our clinic is renowned across the world as a destination for world-class dentistry, with most of our patients flying to us from Australia.

Please contact us today and get a FREE dental consultation.